Hi there everyone! We are back with yet another super informative blog of ours and we can bet that you all are going to love reading it once you have read everything that you need to know in order to make informed decisions regarding t-shirt printing for your future projects. But before we share the information with you all, we would like to take a moment to thank you guys for the love and support that you send our way and for always making sure that your friends, favorite colleagues, and family members are also reading our blogs and making the most of them too and we would love to see more of that happening in the future as well.

You guys must have seen that t-shirt printing has become an art form – allowing individuals and businesses to showcase their creativity and promote their brands. With numerous printing methods available, choosing the most efficient one can be a difficult task especially if you are a newbie. Efficiency depends on various factors such as design complexity, quantity, time constraints, and, of course, budget.

In this part of our blog, we will share a couple of methods that are being followed for t-shirt printing and will later on share the most efficient of them all. Make sure that you read the blog till the end in order to be always ahead in the game.

Direct-to-Garment (DTG) Printing:

Benefit: Detailed and Quick

Direct-to-Garment (DTG) printing has gained popularity due to its ability to produce highly detailed and vibrant designs. This method involves using specialized inkjet printers that directly apply water-based inks onto the fabric. DTG printing is efficient for small to medium runs as it eliminates the need for screen setups, reducing production time and costs. It allows for intricate designs with a wide range of colors, gradients, and shading.

DTG printing also offers excellent color accuracy – making it a preferred choice for reproducing complex artwork or photographs. However, it may be less suitable for bulk orders as printing each shirt individually can be time-consuming. In addition, the cost per shirt may be higher compared to other methods for large quantities.

Heat Transfer Vinyl (HTV):

Benefit: Customization and Durability

Heat Transfer Vinyl (HTV) is a popular method for customizing t-shirts with personalized designs or small batches. It involves cutting designs from colored vinyl sheets and using heat and pressure to transfer them onto the fabric. HTV offers precise designs, vibrant colors and durability. It allows for quick production as the cutting and application process is relatively fast. HTV is an efficient choice for small runs or one-off designs such as individual names or numbers on sports jerseys.

However, for large quantities, HTV may not be the most cost-effective method as the time and labor required for cutting and applying each design can increase production costs.

Dye Sublimation:

Benefit: Full-Color All-Over Prints

Dye sublimation printing is a technique that transfers dye onto t-shirts using heat. The design is first printed onto a transfer paper using special sublimation inks and then heat and pressure are applied to transfer the ink onto the fabric. Dye sublimation is particularly efficient for full-color all-over prints on polyester fabrics. It offers vibrant colors, excellent color fastness and allows for intricate designs without compromising quality.

Dye sublimation is well-suited for small to medium runs and is commonly used for sports jerseys, activewear, and promotional t-shirts. However, there are more efficient methods for cotton or blended fabrics as sublimation inks require polyester to create a permanent bond.

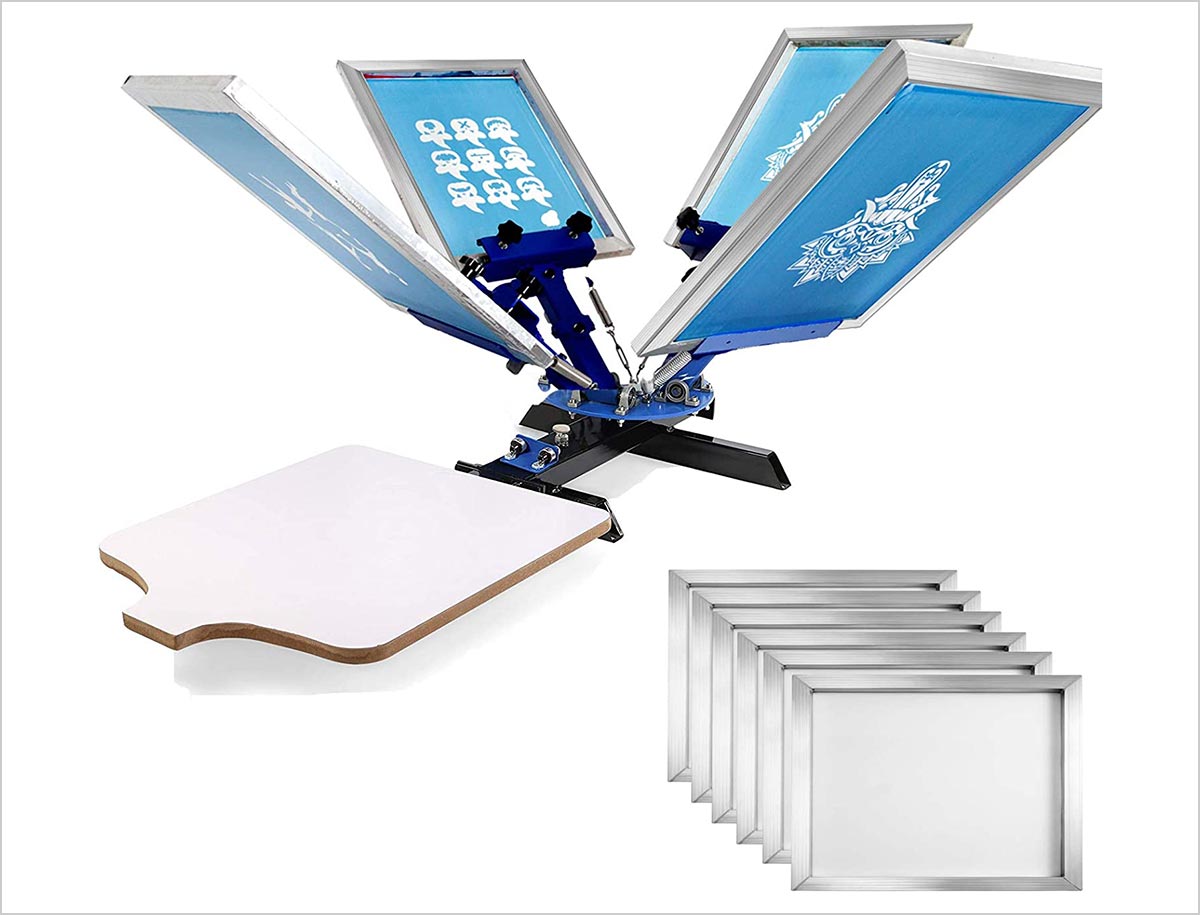

Screen Printing:

Benefit: High-Speed Production

Screen printing which is also known as silkscreen printing is a widely used method for large-scale t-shirt production which makes it very clear that it is the most efficient method for t-shirt printing. This method involves creating a stencil or screen for each color in the design and transferring ink onto the fabric through the screen using a squeegee.

Screen printing excels in high-speed production once the screens are set up – making it highly efficient for large quantities of t-shirts. It offers vibrant colors, durability and versatility across various fabric types. However, it requires separate screens for each color which can make it less suitable for intricate designs with numerous color gradients. Screen printing is an ideal choice for bulk orders as the setup costs are distributed among a larger quantity of shirts resulting in cost savings.

That is all for today, you guys! We hope that you all had an amazing time reading this blog and that you will also share it with your colleagues, friends and family members too who would find it useful for their own businesses and the ones that they are associated with. We would also love to hear your feedback as well so feel free to send that our way and while you are at it, do let us know if you guys have any special requests to make so that we can start working on them and be back here super soon.

– – – – – –

Recommended:

- Digital vs. Offset Printing | Which one is best in 2023?

- What Are The 7 Different Printing Techniques Available?

- Is The Process Printing Industry Dying?

- Difference Between CMYK, Spot Color & Process Color for Printing?

- Looking for the Best Business Card? Try 3D or Letterpress Printing